Why does DPF need to be cleaned?

Diesel DPF cleaning equipment helps you

The DPF of China VI has become an indispensable part of diesel vehicles. A diesel particulate matter filter (DPF) is a device that prevents particulate matter produced by diesel engines from entering the atmosphere.

By the sixth stage of China, DPF has become an essential part of the diesel engine after-treatment system. Due to the high technical content and high cost of this system, how to use and maintain the DPF reasonably is a matter that the owners of the National Phase VI must pay attention to.

Why does DPF need to be cleaned?

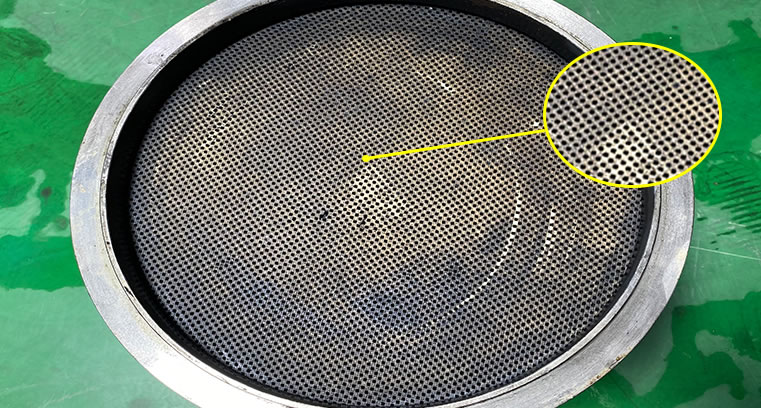

The function of the DPF is equivalent to a filter, which can intercept various particulate matter in the engine exhaust, mainly carbon particles, which are generally black smoke. However, as the number of intercepted particles increases, the DPF will also be blocked by carbon particles, resulting in an increase in engine exhaust back pressure, and a decrease in power and economy. At this time, it is necessary to use some methods to burn these intercepted particles and turn them into gas to be discharged to empty the space inside the DPF. This process is DPF regeneration.

With the use of engine oil, the ash content in the DPF will continue to accumulate and occupy the space originally used to capture carbon particles. Since neither active regeneration nor passive regeneration can clean these substances, other cleaning methods are needed. The KINGKAR DPF cleaning machine adopts advanced water washing technology to efficiently clean the carbon deposits in the DPF, protect the DPF from damage, and greatly save the cost of replacing the DPF.

If you want to know more about the DPF cleaning machine, please contact KINGKAR.