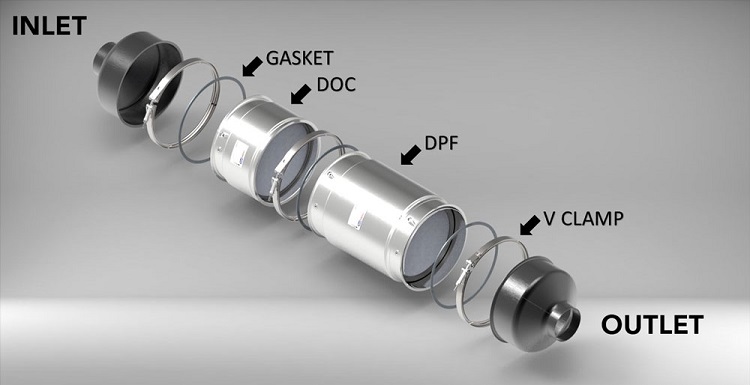

DOC & DPF Cleaning Methods You Must Know

DOC is the core of China VI post-processor

After the DOC is blocked, it will not be able to provide enough heat and oxygen to the DPF through the oxidation-reduction reaction, so the DPF cannot be passively regenerated. The DPF will have poor airflow and insufficient temperature, which will cause the SCR to block the urea crystals. Therefore, the DOC is national VI. The core of the post-processor. There are three major reasons for DOC blockage: 1. Diesel and engine oil with excessive flow rate are added, 2. The air filter is bad, 3. Long-term low-speed driving.

Should DOC be blocked with fire or washed with water?

The blockage of DOC is a high-temperature sintered product that has been accumulated for a long time. The components are unburned colloid and sulfate. These high-temperature sintered products are not afraid of fire. 90% of the sulfate is soluble in water, and the unburned gum is also soluble in water. In our daily life, the range hood in our kitchen is cleaned with hot water. Therefore, it is reasonable for the DOC to use the cleaning agent heating cycle to clean, but the electric furnace does not solve the problem.

Should DOC be blocked with fire or washed with water?

The blockage of DOC is a high-temperature sintered product that has been accumulated for a long time. The components are unburned colloid and sulfate. These high-temperature sintered products are not afraid of fire. 90% of the sulfate is soluble in water, and the unburned gum is also soluble in water. In our daily life, the range hood in our kitchen is cleaned with hot water. Therefore, it is reasonable for the DOC to use the cleaning agent heating cycle to clean, but the electric furnace does not solve the problem.

The significance of DPF artificial regeneration

What DPF intercepts is carbon ash, which is carbon + ash as the name implies. The passive and active regeneration of the DPF on the car will also generate a certain amount of ash. During the regeneration process, only carbon particles are burned, and the ash cannot be burned. As the regeneration times are repeated, the ash that cannot be burned will increase. The more accumulated, the more active regeneration will eventually become ineffective, which requires the DPF to be dismantled for manual regeneration and cleaning.

Analysis of advantages and disadvantages of electric furnace regeneration DPF

The use of electric furnace heating to regenerate DPF has the advantage of being able to completely burn off carbon particles. The disadvantage is that the regeneration time takes 6 hours, the power consumption is large, and the regeneration cycle is too long. After the electric furnace is regenerated, the ash cannot be removed, and the DPF must be cleaned.

Using artificial air guns to blow soot has low efficiency and huge pollution, and it is expensive to use machines to blow soot.

National Four water washing equipment can not dredge DPF

DPFs of different diameters have meshes as high as 10,000 to 30,000. The water flow of conventional washing equipment is damped by so many meshes and wall orifices. The water flow will become soft and weak, unable to flush out the carbon dust blockage. National IV Most of the water washing equipment does not have a carbon dust filter device, and the blockage in the DPF intake port will be flushed into the exhaust port during the cycle cleaning, resulting in the DPF never being able to be washed through.

National VI water washing equipment can dredge DPF

KINGKAR DPF equipment is superimposed with wave peak surge technology in heating cycle cleaning, one-shot air purge technology, and a carbon dust filter device connected in series in the circulating water circuit. Therefore, our national six water washing equipment can remove the carbon dust blockage in the DPF indiscriminately at one time, and it only takes about one hour to clean a DPF.

National VI water washing equipment can dissolve SCR urea crystals

National VI SCR urea crystals are essentially different from National IV SCR urea crystals. National IV SCR is located at the engine exit. The urea crystals have been baked by the engine at high exhaust temperature and have turned into calcifications. The National Sixth SCR is in the third quarter. As analyzed earlier, its urea crystals are closely related to the insufficient discharge temperature of the DPF upstream. Therefore, its urea crystals will not be calcified. Many practices have proved that with our National VI water washing equipment, the large urea crystals inside the National VI SCR can be completely melted away.

Summary of China VI post-processor regeneration

After the DOC is blocked, the oxidation-reduction capacity is reduced, and it cannot provide enough heat and oxygen to the DPF, and the passive regeneration capacity of the DPF is reduced, which will form a carbon ash blockage. The airflow of DPF into the SCR mixing chamber will be blocked and the temperature will drop. The insufficient temperature in the SCR mixing chamber will result in poor atomization of the urea sprayed from the urea nozzle to form condensation, which will form urea crystals, which will eventually cause the surface of the SCR mixing chamber and SCR honeycomb to be completely blocked by the urea crystals.

Theory and practice have proved that if any section of the National VI post processor is blocked, the three sections will be blocked to varying degrees. Therefore, the DOC, DPF, and SCR must be cleaned at the same time to cure both the symptoms and the root causes.

If you want to know more about DPF, please contact KINGKAR.