DPF/FAP filters and SCR catalysts cleaning technology

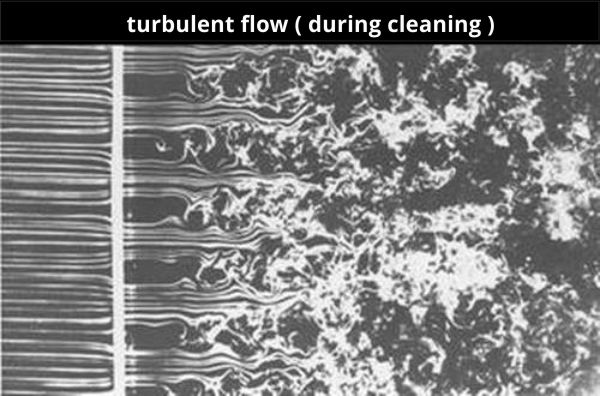

KingKar DPF cleaning technology uses warm water flushing with the cleaner agent and high-pressure air purging work alternately, three treatments together,100% clean and will not cause a secondary blockage. The movement of the liquid (working fluid) is forced by the external pressure which must overcome the flow resistance in the filter channels. At turbulent flow, streams of liquid mix to form whirls that easily penetrate and remove solid particles in the microporous septum of the filter channels.

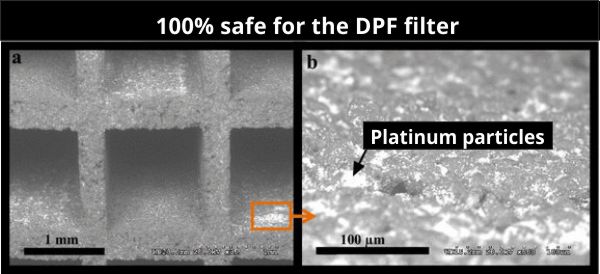

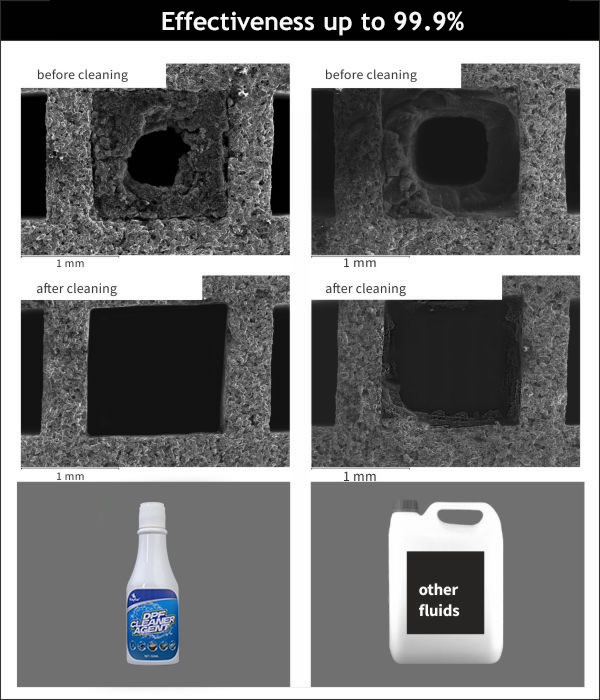

Kingkar DPF cleaning machine work with the cleaner agent enhances the cleaning effect, cleaning effect can reach nearly 100% cleaning efficiency. The main component of the cleaner agent is composed of several organic carboxylic acid chelating agents and solubilizing aids and corrosion inhibitors. It can selectively chelate the metal ash, thereby destroying the organizational structure of the blockage, making the stubborn blockage lose, and removing the loose blockage through the powerful water and airflow of the equipment. In this way, Kingkar DPF machine can efficiently clean DPFs, and the cleaning effect reaches 100% efficiency

During cleaning, the flow geometry of the DPF filter provides resistance with the simultaneous creation of high-velocity flow and high shear stress, which is the main mechanism for removing compressed deposits in the filter channels.

In addition, the flow resistance is caused by the appropriate viscosity of the cleaner agent, which causes that during the movement of liquid molecules, a phenomenon similar in effect to friction occurs.

The technology allows for the very precise removal of all types of solid particles (cerium, soot, ash, oils) from both the outlet and inlet passages of the filter.

The technology includes:

Cleaning process:

- Inspection of the honeycomb with an endoscope. The filter cartridge that qualifies for cleaning can not be cracked, melted.

- Installing the filter in the machine

- Application of the KingKar DPF cleaner agent

- Starting the cleaning process. Water temperature 65-70 ℃

- Press START and wait

- Cleaning (60 mins)

- Drying (around 30 min)

- Taking pictures of the filter cartridge with an inspection camera

- Preparation of the report.