Founded in 2001, Kingkar Eco-Technologies Co., Ltd. is a leading manufacturer of diesel particulate filters, providing innovative DPF Cleaning Machine to customers worldwide. We are committed to providing our customers with the most reliable and effective solutions.

Kingkar guarantee results. We clean and recondition DPF systems every day using our patented process, which makes us the industry leader in DPF cleaning and reconditioning. If you are interested in joining the diesel industry and becoming part of our industry-leading team, please contact us, or take a look at our range of services and products. Designed to suit any budget, our DPF cleaning equipment set is designed to break down ash and soot without damaging the precious metals in your DPF system, all of which allows you to restore your DPF to like-new condition.

DPF Cleaning Machine uses high-tech purification technology to accurately clean diesel vehicles of different brands and models, effectively extending the service life of DPF filters.

Regarding DPF Cleaning Machine, Kingkar has prepared some relevant professional knowledge documents for everyone, hoping to provide some help to you who are interested in DPF Cleaning Machine.

What is the principle of DPF cleaning machine?

1Firstly, it is important to read the user manual carefully before operating the machine. This will provide instructions on how to properly set up, use, and maintain the equipment. Secondly, make sure to wear protective gear, such as gloves and goggles, when handling the machine and the chemicals involved in the cleaning process. This will help prevent any potential harm from exposure to the cleaning agents. Next, it is crucial to use the correct cleaning solution for the specific type of diesel particulate filter being cleaned. Using the wrong solution can damage the filter and potentially cause harm to the operator. 2One of the main advantages of a DPF Cleaning Machine is improved fuel economy. When a DPF becomes clogged with soot particles, it restricts the flow of exhaust gases and can cause the vehicle to use more fuel to compensate. By cleaning the filter, the DPF cleaning machine helps to improve the vehicle’s fuel efficiency and save money on fuel costs.Another advantage is that it helps to prolong the life of the DPF. urther, using a DPF cleaning machine can also reduce harmful emissions from the vehicle.

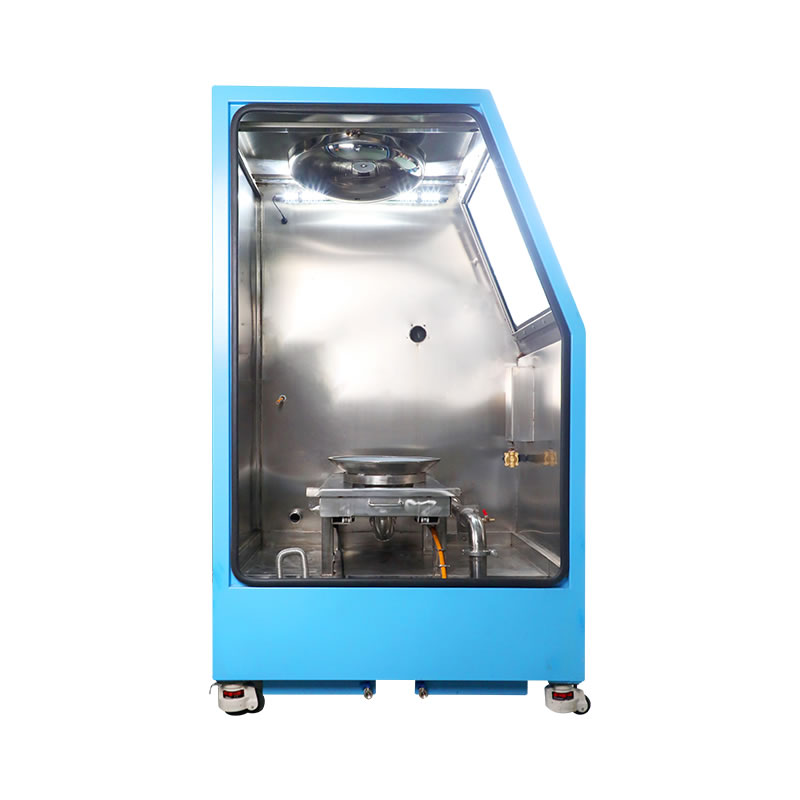

DPF Cleaning Machine is an efficient and intelligent diesel particulate filter cleaning equipment that uses advanced technology and has multiple technical attributes to provide users with professional and reliable cleaning services.

DPF Cleaning Machine has a variety of safety protection functions, including automatic power-off over temperature, voltage protection, leakage protection, etc., to ensure users’ safe use. At the same time, the equipment also has a removable filter, which facilitates users to replace the filter and improves the service life. In general, the technical attributes of DPF Cleaning Machine products are mature and stable, reliable and durable, and it is an indispensable industrial cleaning equipment.

DPF Cleaning Machine–An Ultimate FAQ Guide.

1.How does a DPF cleaning machine prevent equipment damage?

2.Is the DPF cleaning machine suitable for vehicles with turbocharged engines?

3.Can a DPF cleaning machine clean hard-to-reach corners?

4.How long does the cleaning process of a DPF cleaning machine take?

5.What matters need to be paid attention to in the maintenance and upkeep of DPF cleaning machines?

6.What is the estimated cost savings of using a DPF cleaning machine?

7.What are the design features of DPF cleaning machines?

8.How does the DPF cleaning machine comply with environmental regulations?

9.How does the DPF cleaning machine affect vehicle inspection and compliance?

10.How does the DPF cleaning machine impact vehicle performance?

11.What are the shell materials and protection levels of DPF cleaning machines?

12.Does the DPF cleaning machine have automatic control function?

13.What are the dimensions and weight of a DPF cleaning machine?

14.How much does it cost to repair and replace DPF cleaning machine parts?

15.How does the DPF cleaning machine compare to manual filter replacement?

16.Is the use of DPF cleaning machine easy to understand?

17.Does the DPF cleaning machine have the characteristics of energy saving and environmental protection?

18.What is the service life and quality guarantee of a DPF cleaning machine?

19.Are there any restrictions on the cleaning methods of DPF cleaning machines?

20.Does the DPF cleaning machine have smart functions?

21.What are the different models of DPF cleaning machines?

1.How does a DPF cleaning machine prevent equipment damage?

A DPF (Diesel Particulate Filter) cleaning machine works to ensure that diesel engines remain at optimal performance levels by preventing potential equipment damage. This is achieved through a process of removing harmful soot particles from the filter, as well as ash build-up that can restrict air flow and reduce engine efficiency. By regularly cleaning the filter, the DPF cleaning machine helps to prevent damaging build-up and maintain engine performance, leading to longer equipment lifespan and cost savings for the user.

2.Is the DPF cleaning machine suitable for vehicles with turbocharged engines?

The DPF cleaning machine is a special tool designed for cleaning vehicle diesel particulate filters (DPF). Although it can be used in a variety of vehicles, including those with turbocharged engines, it is important to follow the instructions to ensure proper use. Generally speaking, DPF cleaning machines can effectively clean and maintain the DPF of turbocharged engine vehicles, thereby improving the performance and life of the engine.

3.Can a DPF cleaning machine clean hard-to-reach corners?

Yes, a DPF cleaning machine has the ability to effectively clean even the most hard-to-reach corners, ensuring thorough and efficient maintenance of diesel particulate filters. With advanced technology and powerful cleaning methods, these machines are designed to reach every nook and cranny of a DPF, removing built-up soot and ash to restore its performance. This not only improves the overall health of the engine and reduces harmful emissions, but also extends the lifespan of the DPF. Whether it’s a constricted area or a complex shape, a DPF cleaning machine can effectively tackle any challenge to ensure optimal filter performance.

4.How long does the cleaning process of a DPF cleaning machine take?

The duration of the cleaning process for a DPF cleaning machine varies depending on the machine and the level of cleaning required. Generally, it can take anywhere from 30 minutes to a few hours to complete the cleaning process. The machine uses specialized techniques and equipment to effectively clean and remove deposits from the diesel particulate filter, ensuring optimal performance and longevity.

5.What matters need to be paid attention to in the maintenance and upkeep of DPF cleaning machines?

Maintaining and upkeep of DPF cleaning machines is essential to ensure their proper functioning and longevity. There are several important factors to consider when performing maintenance on these machines. Firstly, regular cleaning and inspection of the machine’s filters and components is necessary to remove any buildup of ash or soot. Additionally, the correct disposal of collected waste materials is crucial to prevent environmental pollution. It is also important to follow the manufacturer’s recommendations for using the correct cleaning solutions and operating the machine at proper pressure and temperature. Constant monitoring and timely servicing of DPF cleaning machines can help to avoid costly repairs and ensure efficient operation.

6.What is the estimated cost savings of using a DPF cleaning machine?

The estimated cost savings of using a DPF cleaning machine can vary depending on individual circumstances, but on average, it can save businesses and individuals thousands of dollars annually. This is due to the fact that the machine effectively cleans and restores the exhaust systems of diesel vehicles, reducing the need for costly replacements and repairs. Additionally, with a properly cleaned DPF, the vehicle’s fuel efficiency can improve, leading to further cost savings on fuel expenses. Overall, investing in a DPF cleaning machine can result in significant financial benefits in the long run.

7.What are the design features of DPF cleaning machines?

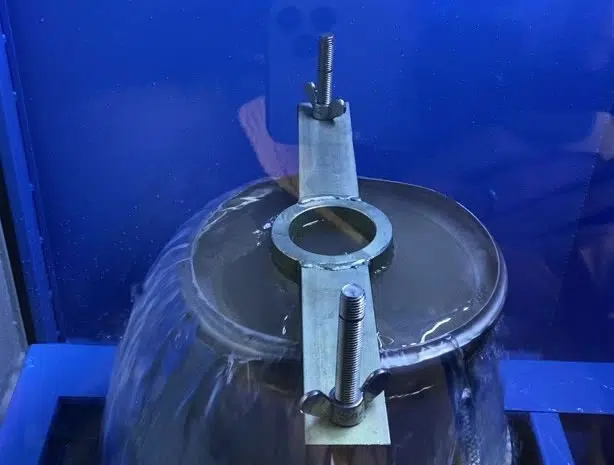

DPF cleaning machines are specifically designed to clean diesel particulate filters, which are crucial components in diesel engines. These machines utilize advanced technology and innovative design features to effectively remove soot, ash, and other contaminants from the filter, prolonging its lifespan and ensuring optimal engine performance. Some of the key design features of DPF cleaning machines include high-pressure water jets, efficient heating systems, intricate filtration systems, and user-friendly controls. These features work together to provide a thorough and efficient cleaning process, making DPF cleaning machines an essential tool for maintaining the efficiency and longevity of diesel engines. DPF cleaning machines are specialized equipment designed to effectively clean diesel particulate filters, which are critical components of modern diesel engines used in vehicles and heavy machinery. These machines have several design features that enable them to efficiently remove soot, ash, and other contaminants from the filters. They typically have high-pressure nozzles and pumps that create powerful water jets to dislodge and flush out the accumulated particles. Some models also use vibration technology to shake off the trapped debris. Additionally, these machines are equipped with filtration systems to separate and capture the removed contaminants, preventing them from polluting the environment. Some advanced models also have integrated heating systems to aid in the cleaning process. Overall, DPF cleaning machines are designed to provide thorough and efficient cleaning while being user-friendly and environmentally conscious.

8.How does the DPF cleaning machine comply with environmental regulations?

The DPF cleaning machine is designed to meet strict environmental regulations by utilizing advanced technology and techniques. This machine uses a cleaning process that does not involve any harsh chemicals, ensuring that there are no harmful emissions or by-products released into the environment. Furthermore, the machine is equipped with advanced filters and systems that effectively capture and contain any debris or particles during the cleaning process. Additionally, the DPF cleaning machine is regularly tested and certified to comply with environmental regulations and standards set by governing bodies, providing assurance that it is a safe and environmentally-friendly solution for diesel particulate filter cleaning.

9.How does the DPF cleaning machine affect vehicle inspection and compliance?

The DPF cleaning machine plays a crucial role in ensuring that vehicles are able to pass inspections and comply with emission regulations. By effectively cleaning diesel particulate filters, the machine helps to reduce harmful exhaust emissions, which is a key factor in meeting regulatory standards. This not only helps to maintain the vehicle’s overall performance and longevity, but also contributes to the overall improvement of air quality. Ultimately, the use of a DPF cleaning machine is essential in helping vehicles to meet inspection requirements and remain in compliance with environmental regulations.

10.How does the DPF cleaning machine impact vehicle performance?

The DPF cleaning machine is designed to effectively clean the diesel particulate filter, which can have a significant impact on a vehicle’s performance. By removing built-up particles and ash from the filter, it can help improve engine efficiency and reduce emissions. This, in turn, can result in better fuel economy, increased power and torque, and smoother overall operation of the vehicle. Regular cleaning with the DPF cleaning machine can also help prevent potential damage and extend the lifespan of the filter, ultimately benefiting the performance of the vehicle.

11.What are the shell materials and protection levels of DPF cleaning machines?

The shell materials of DPF cleaning machines typically consist of high-strength steel or aluminum alloy, providing durability and resistance to corrosion and wear. As for protection levels, these machines are designed to effectively remove particulate matter and soot from diesel particulate filters, ensuring optimal performance and reducing harmful emissions. They may also incorporate advanced filtration systems and safety features to protect the user and surrounding environment during the cleaning process.

12.Does the DPF cleaning machine have automatic control function?

The DPF cleaning machine is equipped with an automatic control function. With this feature, the machine is able to accurately monitor and adjust the cleaning process, ensuring efficient and thorough cleaning of the diesel particulate filter. This automatic control function provides convenience and peace of mind for users, as it reduces the need for constant manual monitoring and makes the cleaning process more streamlined and efficient.

13.What are the dimensions and weight of a DPF cleaning machine?

A DPF cleaning machine is a specialized piece of equipment used to clean diesel particulate filters. It typically has dimensions of approximately 2-3 feet in width and height and a length of 4-5 feet. The weight of a DPF cleaning machine can vary depending on the model, with smaller ones weighing around 200-300 pounds and larger ones weighing up to 1000 pounds. Overall, these machines are compact and sturdy, making them easy to transport and use in various settings.

14.How much does it cost to repair and replace DPF cleaning machine parts?

The cost of repairing and replacing parts for a DPF cleaning machine varies depending on the specific parts needed and the brand of the machine. Generally, it can range from a few hundred to several thousand dollars. Factors such as the age and condition of the machine, as well as the location and expertise of the technician, can also affect the overall cost. It is important to regularly maintain and service the DPF cleaning machine to minimize the need for costly repairs and replacements.

15.How does the DPF cleaning machine compare to manual filter replacement?

The DPF cleaning machine is a more efficient and cost-effective alternative to manual filter replacement. With the machine, the filter can be thoroughly cleaned without the need for expensive replacement parts, saving time and money. Additionally, the machine allows for a more thorough cleaning process, removing clogs and built-up soot that may not be fully addressed through manual replacement. Overall, the DPF cleaning machine provides a more effective, convenient, and environmentally friendly solution for maintaining and extending the lifespan of diesel particulate filters.

16.Is the use of DPF cleaning machine easy to understand?

Yes, DPF cleaning machines are designed to be user-friendly and easy to operate. There are simple step-by-step instructions that anyone with basic mechanical knowledge can operate. In addition, training and support are provided to ensure users fully understand how to use the DPF cleaning machine effectively. With proper training and maintenance, the use of a DPF cleaning machine can be easily understood and incorporated into regular vehicle maintenance routines.

17.Does the DPF cleaning machine have the characteristics of energy saving and environmental protection?

The DPF cleaning machine is a type of equipment that is used to remove particulate matter from diesel engine exhaust. It is designed to not only effectively clean the filters, but also have the key features of energy efficiency and environmental friendliness. By reducing harmful emissions and utilizing energy-saving technologies, the DPF cleaning machine helps to promote a cleaner and healthier environment.

18.What is the service life and quality guarantee of a DPF cleaning machine?

A DPF cleaning machine typically has a service life of around 5-10 years with proper maintenance and usage. The quality guarantee of a DPF cleaning machine may vary depending on the manufacturer and their specific warranty policies. However, most reputable manufacturers offer at least a 1-2 year warranty for their machines, ensuring reliable performance and customer satisfaction.

19.Are there any restrictions on the cleaning methods of DPF cleaning machines?

The cleaning method of DPF cleaning machine is step-by-step, depending on the specific equipment. These steps may include recommended cleaning techniques, compatible cleaners and safety precautions. Before using your DPF cleaning machine, be sure to review the relevant instructions and guidelines to ensure correct and effective use.

20.Does the DPF cleaning machine have smart functions?

As technology advances, many industries are incorporating smart features into their machinery. This has also been seen in the field of automotive maintenance, with the development of smart DPF cleaning machines. These machines are designed to efficiently and effectively clean diesel particulate filters (DPF), while also incorporating advanced technology such as sensor systems, automatic backflushing, and data storage capabilities. With these smart functions, DPF cleaning machines are not only more efficient, but also offer added convenience and accuracy for users.

21.What are the different models of DPF cleaning machines?

There are several different models of DPF (diesel particulate filter) cleaning machines, each with their own unique features and processes. These models include manual machines that require an operator to physically clean the filter, automated machines with advanced cleaning systems, and mobile units that can be easily transported and used on-site. Some models also integrate technologies such as ultrasonic cleaning or pulse flow technology for more efficient and thorough DPF cleaning. Overall, these machines offer various options for effectively removing accumulated soot and ash from diesel filters, ensuring optimal engine performance and emission control.

tag: DPF Cleaning Machine 6.0,DPF Cleaning Machine 5.0,DPF Cleaner Agent