Kingkar Eco-Technologies Co., Ltd. has a professional team and advanced production equipment, which can customize DPF Cleaning Machine of different specifications according to the specific needs of customers to meet the cleaning needs of different types of vehicles.

In the early 2000s, Kingkar began researching how to improve the cleaning efficiency of diesel particulate filters (referred to as digital filters) for DPF cleaning. While we brought our first machine to the market in 2001, we continued to research, innovate and develop what we believe is the most effective DPF cleaning method available today.

DPF Cleaning Machine needs to use professional cleaning fluid during use. This is because the cleaning fluid has strong drilling ability and can completely dissolve carbon deposits and particulate matter to ensure the cleaning effect.

Regarding DPF Cleaning Machine, Kingkar has prepared some relevant professional knowledge documents for everyone, hoping to provide some help to you who are interested in DPF Cleaning Machine.

What are the precautions for DPF cleaning machine?

1Firstly, it is important to read the user manual carefully before operating the machine. This will provide instructions on how to properly set up, use, and maintain the equipment. Secondly, make sure to wear protective gear, such as gloves and goggles, when handling the machine and the chemicals involved in the cleaning process. This will help prevent any potential harm from exposure to the cleaning agents. Next, it is crucial to use the correct cleaning solution for the specific type of diesel particulate filter being cleaned. Using the wrong solution can damage the filter and potentially cause harm to the operator. 2The principle of a DPF Cleaning Machine is based on the process of regeneration, which removes accumulated soot and debris from the diesel particulate filter (DPF). This is achieved by heating the filter and using a combination of air flow and specialized cleaning solutions to break down and remove the build-up of particles. The machine also utilizes a high-pressure vacuum to suck out any remaining debris. This process ensures that the DPF is fully cleaned and restored to its optimal functioning state, leading to improved engine performance and reduced emission levels. Proper maintenance and regular cleaning with a DPF cleaning machine is crucial for reducing vehicle downtime and keeping engines running efficiently.

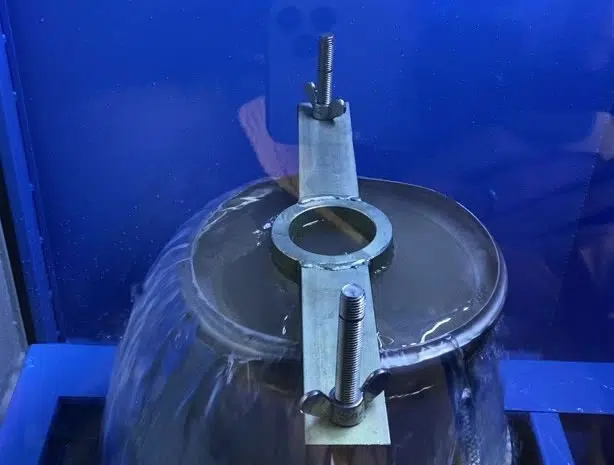

DPF Cleaning Machine adopts ultrasonic cleaning technology, which can completely remove impurities such as oil stains and carbon deposits, effectively ensuring the cleaning effect. Secondly, the equipment is equipped with an intelligent control system that can automatically identify and optimize cleaning procedures according to different types of particle filters, achieving fully automated operation and improving cleaning efficiency.

The DPF Cleaning Machine has strong pressure and flow, which can fully flush all corners inside the filter, effectively remove stubborn stains and improve cleaning quality. At the same time, the equipment is equipped with a high-precision pressure control system that can automatically adjust the pressure according to different types of filters to avoid filter damage caused by excessive cleaning.

DPF Cleaning Machine–An Ultimate FAQ Guide.

1.Can the DPF cleaning machine clean multiple devices at the same time?

2.What matters need to be paid attention to in the maintenance and upkeep of DPF cleaning machines?

3.How does the DPF cleaning machine compare to other maintenance procedures?

4.Is the DPF cleaning machine suitable for vehicles with turbocharged engines?

5.Can a DPF cleaning machine clean multiple contaminants?

6.How does the DPF cleaning machine remove ash from the filter?

7.What are the shell materials and protection levels of DPF cleaning machines?

8.How does a DPF cleaning machine work?

9.How does the DPF cleaning machine affect vehicle inspection and compliance?

10.Can the DPF cleaning machine be used for both light and heavy-duty vehicles?

11.What skills are required to use a DPF cleaning machine?

12.How does the DPF cleaning machine compare to manual filter replacement?

13.Does the DPF cleaning machine have the characteristics of energy saving and environmental protection?

14.What are the dimensions and weight of a DPF cleaning machine?

15.Is the use of DPF cleaning machine easy to understand?

16.What are the different models of DPF cleaning machines?

17.What is a DPF cleaning machine?

18.How efficient are DPF cleaning machines?

19.Is the operation method of DPF cleaning machine harmful to the environment?

20.Do DPF cleaning machines require special ventilation equipment?

21.Compared with traditional cleaning methods, what are the advantages of DPF cleaning machines?

22.How much does it cost to repair and replace DPF cleaning machine parts?

23.Does the DPF cleaning machine have automatic cleaning function?

1.Can the DPF cleaning machine clean multiple devices at the same time?

The DPF cleaning machine is designed to effectively clean diesel particulate filters, but its capabilities in cleaning multiple devices at the same time may vary depending on the specific machine. Some models may have the capacity to clean multiple devices simultaneously, while others may be only able to clean one device at a time. It is important to check the specifications of the specific DPF cleaning machine to determine its capabilities in terms of cleaning multiple devices at once.

2.What matters need to be paid attention to in the maintenance and upkeep of DPF cleaning machines?

Maintaining and upkeep of DPF cleaning machines is essential to ensure their proper functioning and longevity. There are several important factors to consider when performing maintenance on these machines. Firstly, regular cleaning and inspection of the machine’s filters and components is necessary to remove any buildup of ash or soot. Additionally, the correct disposal of collected waste materials is crucial to prevent environmental pollution. It is also important to follow the manufacturer’s recommendations for using the correct cleaning solutions and operating the machine at proper pressure and temperature. Constant monitoring and timely servicing of DPF cleaning machines can help to avoid costly repairs and ensure efficient operation.

3.How does the DPF cleaning machine compare to other maintenance procedures?

The DPF cleaning machine is a highly efficient and cost-effective tool for maintaining the diesel particulate filter. Compared to other maintenance procedures, such as manual cleaning or replacement, it offers a faster and more thorough cleaning process, resulting in improved performance and extended filter life. Additionally, the DPF cleaning machine is environmentally friendly as it uses advanced technologies that do not produce harmful chemicals or emissions. With its convenience and effectiveness, the DPF cleaning machine has become a preferred choice for diesel vehicle owners worldwide.

4.Is the DPF cleaning machine suitable for vehicles with turbocharged engines?

The DPF cleaning machine is a special tool designed for cleaning vehicle diesel particulate filters (DPF). Although it can be used in a variety of vehicles, including those with turbocharged engines, it is important to follow the instructions to ensure proper use. Generally speaking, DPF cleaning machines can effectively clean and maintain the DPF of turbocharged engine vehicles, thereby improving the performance and life of the engine.

5.Can a DPF cleaning machine clean multiple contaminants?

A DPF cleaning machine is a specialized tool designed to clean the diesel particulate filter in a vehicle’s exhaust system. It uses a combination of heat, air, and specially formulated cleaning solutions to remove particulates and other contaminants that can clog the filter. However, it’s important to note that while it can effectively clean multiple contaminants, it may not be able to remove all types of build-up or damage. The effectiveness of the cleaning process depends on the severity and type of contamination present in the filter. Therefore, thorough inspection and evaluation are necessary to determine the best course of action for cleaning the DPF.

6.How does the DPF cleaning machine remove ash from the filter?

The DPF cleaning machine uses a combination of compressed air, heat, and cleaning chemicals to remove built-up ash from the filter. First, the machine blasts compressed air into the filter, dislodging loose particles and pushing them towards the outlet. Then, heat is applied to the filter to break up and loosen more stubborn ash particles. Finally, cleaning chemicals are introduced to dissolve and wash away remaining ash and soot. The resulting clean filter allows for better engine performance and reduced emissions.

7.What are the shell materials and protection levels of DPF cleaning machines?

The shell materials of DPF cleaning machines typically consist of high-strength steel or aluminum alloy, providing durability and resistance to corrosion and wear. As for protection levels, these machines are designed to effectively remove particulate matter and soot from diesel particulate filters, ensuring optimal performance and reducing harmful emissions. They may also incorporate advanced filtration systems and safety features to protect the user and surrounding environment during the cleaning process.

8.How does a DPF cleaning machine work?

A DPF (Diesel Particulate Filter) cleaning machine is a specialized device used to clean diesel particulate filters, which are essential components of diesel engines that help reduce emissions. The machine works by using a combination of chemicals and high-pressure air or water to physically remove the accumulated soot and ash buildup from the filter. This process, known as regeneration, helps to restore the filter’s efficiency and ensure the engine maintains optimal performance. The cleaning machine also includes sensors and monitoring systems to track the progress and effectiveness of the cleaning process. Regular use of a DPF cleaning machine is crucial in maintaining the longevity and effectiveness of diesel engines.

9.How does the DPF cleaning machine affect vehicle inspection and compliance?

The DPF cleaning machine plays a crucial role in ensuring that vehicles are able to pass inspections and comply with emission regulations. By effectively cleaning diesel particulate filters, the machine helps to reduce harmful exhaust emissions, which is a key factor in meeting regulatory standards. This not only helps to maintain the vehicle’s overall performance and longevity, but also contributes to the overall improvement of air quality. Ultimately, the use of a DPF cleaning machine is essential in helping vehicles to meet inspection requirements and remain in compliance with environmental regulations.

10.Can the DPF cleaning machine be used for both light and heavy-duty vehicles?

Yes, the DPF cleaning machine is suitable for both light and heavy-duty vehicles. It uses advanced technology to effectively clean and regenerate diesel particulate filters, providing a solution for vehicles of all sizes and engine types. By removing built-up soot and ash from the filter, the machine helps improve engine performance and reduce emissions, making it a valuable tool for maintaining the health and efficiency of both light and heavy-duty vehicles. With its versatility and effectiveness, the DPF cleaning machine is a must-have for any fleet or workshop.

11.What skills are required to use a DPF cleaning machine?

To effectively use a DPF cleaning machine, various skills are required. Firstly, a sound understanding of the different parts of the DPF system and how they function is essential. This includes knowledge of the filters, sensors, and other components. Additionally, the user should be acquainted with the specific make and model of the machine being used. Good technical and mechanical skills are also necessary in order to operate and maintain the machine properly. Familiarity with safety protocols and precautions is also crucial to ensure safe and efficient use of the equipment. Finally, critical thinking and problem-solving skills are needed to troubleshoot any potential issues that may arise during the cleaning process.

12.How does the DPF cleaning machine compare to manual filter replacement?

The DPF cleaning machine is a more efficient and cost-effective alternative to manual filter replacement. With the machine, the filter can be thoroughly cleaned without the need for expensive replacement parts, saving time and money. Additionally, the machine allows for a more thorough cleaning process, removing clogs and built-up soot that may not be fully addressed through manual replacement. Overall, the DPF cleaning machine provides a more effective, convenient, and environmentally friendly solution for maintaining and extending the lifespan of diesel particulate filters.

13.Does the DPF cleaning machine have the characteristics of energy saving and environmental protection?

The DPF cleaning machine is a type of equipment that is used to remove particulate matter from diesel engine exhaust. It is designed to not only effectively clean the filters, but also have the key features of energy efficiency and environmental friendliness. By reducing harmful emissions and utilizing energy-saving technologies, the DPF cleaning machine helps to promote a cleaner and healthier environment.

14.What are the dimensions and weight of a DPF cleaning machine?

A DPF cleaning machine is a specialized piece of equipment used to clean diesel particulate filters. It typically has dimensions of approximately 2-3 feet in width and height and a length of 4-5 feet. The weight of a DPF cleaning machine can vary depending on the model, with smaller ones weighing around 200-300 pounds and larger ones weighing up to 1000 pounds. Overall, these machines are compact and sturdy, making them easy to transport and use in various settings.

15.Is the use of DPF cleaning machine easy to understand?

Yes, DPF cleaning machines are designed to be user-friendly and easy to operate. There are simple step-by-step instructions that anyone with basic mechanical knowledge can operate. In addition, training and support are provided to ensure users fully understand how to use the DPF cleaning machine effectively. With proper training and maintenance, the use of a DPF cleaning machine can be easily understood and incorporated into regular vehicle maintenance routines.

16.What are the different models of DPF cleaning machines?

There are several different models of DPF (diesel particulate filter) cleaning machines, each with their own unique features and processes. These models include manual machines that require an operator to physically clean the filter, automated machines with advanced cleaning systems, and mobile units that can be easily transported and used on-site. Some models also integrate technologies such as ultrasonic cleaning or pulse flow technology for more efficient and thorough DPF cleaning. Overall, these machines offer various options for effectively removing accumulated soot and ash from diesel filters, ensuring optimal engine performance and emission control.

17.What is a DPF cleaning machine?

A DPF cleaning machine is a special type of equipment used to clean diesel particulate filters (DPFs), which are designed to remove soot and other harmful particles from the exhaust system of diesel engines. The cleaning process involves using high-pressure air and specialized cleaning solutions to dislodge and remove the accumulated particles, allowing the DPF to function properly and meet emissions regulations.

18.How efficient are DPF cleaning machines?

DPF cleaning machines are highly efficient tools used to clean diesel particulate filters (DPFs). They use specialized techniques and technology to remove trapped soot and other contaminants from the filters, restoring their efficiency and prolonging their lifespan. These machines are able to clean DPFs quickly and effectively, saving time and money compared to traditional manual cleaning methods. With their high efficiency and reliability, DPF cleaning machines have become an essential tool for maintaining the performance of diesel engines.

19.Is the operation method of DPF cleaning machine harmful to the environment?

The environmental impact of DPF cleaning machines has been a topic of concern. Despite their efficiency in cleaning diesel particulate filters, there is some concern about the potential harm they may cause to the environment. Many experts believe that the operation method of these machines may release harmful chemicals and pollutants into the air, soil, and water, resulting in negative effects on the environment. It is important that proper precautions and regulations are in place to mitigate any potential harm and ensure the safe use of DPF cleaning machines.

20.Do DPF cleaning machines require special ventilation equipment?

Yes, DPF cleaning machines do require special ventilation equipment. This is because the cleaning process involves burning off trapped soot particles, which can release harmful emissions such as carbon monoxide and nitrogen oxides. A proper ventilation system helps to safely remove these emissions and maintain a healthy working environment.

21.Compared with traditional cleaning methods, what are the advantages of DPF cleaning machines?

DPF (Diesel Particulate Filter) cleaning machines have a number of advantages over traditional cleaning methods. Firstly, they are much more efficient at removing carbon deposits from the filter, which can quickly build up and cause engine performance issues. Additionally, DPF cleaning machines use advanced technology and specialized detergents to thoroughly clean the filter, ensuring that it is completely free from residue and able to function at its optimal capacity. Furthermore, these machines are quick and easy to use, reducing the downtime of vehicles and minimizing the need for manual labor. Ultimately, DPF cleaning machines offer a more effective and convenient solution for maintaining and prolonging the lifespan of diesel engines.

22.How much does it cost to repair and replace DPF cleaning machine parts?

The cost of repairing and replacing parts for a DPF cleaning machine varies depending on the specific parts needed and the brand of the machine. Generally, it can range from a few hundred to several thousand dollars. Factors such as the age and condition of the machine, as well as the location and expertise of the technician, can also affect the overall cost. It is important to regularly maintain and service the DPF cleaning machine to minimize the need for costly repairs and replacements.

23.Does the DPF cleaning machine have automatic cleaning function?

The DPF cleaning machine is equipped with an automatic cleaning function, allowing for quick and efficient cleaning of diesel particulate filters without the need for manual intervention. This feature ensures a high level of cleanliness and prolongs the lifespan of the filter, resulting in improved engine performance and reduced emissions.

Tag:DPF Cleaning Machine 6.0,DPF Cleaning Machine 5.0,DPF Cleaner Agent